THE STUDIO CASTING CENTER

The Studio Grand Opening on October 17 included the first look at the new 5,000-square-foot James Flaws & Marcia Weber Casting Center, which is slated for completion before the end of the year. The most well-equipped foundry in the United States for large-scale glass casting, the only glass foundry dedicated to artists and designers, and the only facility equipped with state-of-the-art equipment and personnel to support artists in their work, the Casting Center will also support cast commissions. The Casting Center will accommodate all stages of the process to cast works in glass, from mold-making to finished work. Additionally, the Casting Center will be an important disseminator of knowledge of glass casting, encouraging experimentation with new techniques and sharing those investigations through publications and other platforms.

TEACHING NEXT SUMMER

I’m thrilled to be teaching at the Studio next summer! In my class, we will explore innovative 3D printing techniques as part of a comprehensive introduction to kiln-cast glass and cold working. It’s going to be an exciting opportunity to experiment with new processes and expand your creative possibilities.

All Summer 2025 classes will be available for registration starting December 15. Check out the link below for more details!

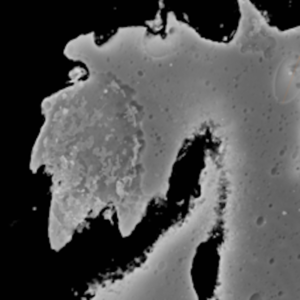

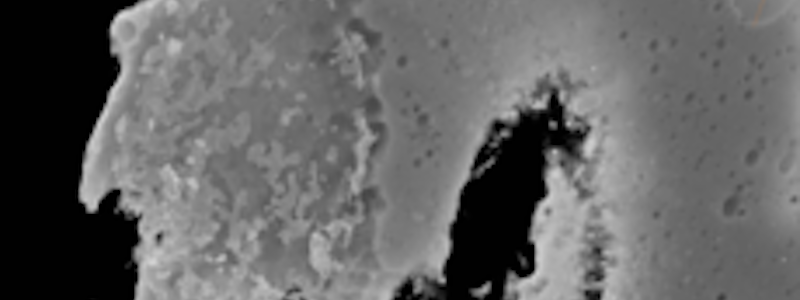

ROMAN CAMEO RESEARCH

In 2019, I collaborated with Bullseye Glass to investigate the potential of creating cameo vessels using hot pressing and pâte de verre techniques. I worked with glass specially formulated by Bullseye to replicate the characteristics of Roman cameo glass and experimented with pressing molten glass into molds. These tests were successful, revealing new insights into how such Roman vessels may have been produced. The results demonstrated how the white layer could have been hot-pressed onto the surface and how rotational scratches on the inner surfaces could have formed. The accompanying image is a CT scan of a 1st-century Roman cameo from the Australian National University’s (ANU) collection. The scan reveals bubbles and glass formations that align with the pâte de verre and pressing methods. This image was captured in collaboration with Dr. Tim Senden and the Research School of Physics & Engineering at ANU.